Test adapter by TOPTEST

Bragi - The Dash

The project

Development of a 12-fold test and programming adapter from TOPTEST for The Dash by Bragi. In the first version of the test adapter only a purely sequential testing was possible because of the dependencies of tests with each other. In version 3.0, the now autonomous tests were placed in a concurrent running TestStand sequence. In addition, individual sockets were prioritized in order to optimally exploit the hardware resources. This resulted in comparison to the initial situation a time saving of 80%.

The task

The Dash is the world's first wireless, intelligent earphones with communication and sensor technology. It was developed by the Munich-based company Bragi in the last 4 years and came in early 2016 on the worldwide market. The entire technology with battery is located in a housing that is barely larger than an earphone. His firm grip in the ear is achieved by a special size adaptable design. The miniaturized circuit boards are manufactured as 12-panel and their processors should be programmed onboard. Subsequently essential basic functions via various interfaces should be tested.

The solution

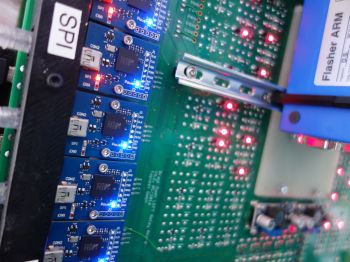

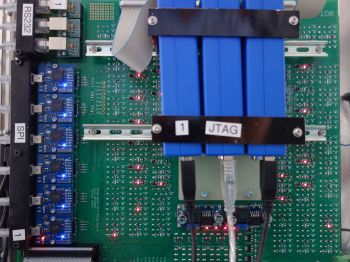

TOPTEST had developed in collaboration with the company ATX a test adapter, which allowed in the first phase only sequential testing and programming. For the connection of programming devices and interfaces, we developed a relay board, which is controlled with the National Instruments USB-IO module 6509. The test software was carry out with NI TestStand, by integrating LabVIEW VIs and Python scripts. For the adaptation of the panel we specially developed a bed of nails with double-sided needles and without wire wrap. The lower needle tip applies here in each case on a via of the relay board, which has a direct connection to the corresponding relay. This has the advantage of shorter lines and the easy interchangeability of the relay boards. A major difficulty has been the delicate nature of the DUT, since the printed circuit boards have no good area for the necessary holding-down.

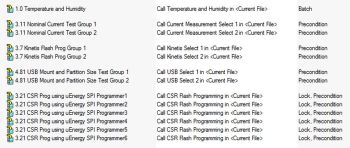

In Version 2.0 we developed a modification of the TestStand test sequence, in which the sequential testing was transferred to a partially parallel testing. With this process, the test time was reduced by 50% already. The TestStand test sequence processed product-specific information, such as binary files and serial numbers that can be accessed from a server. Balance data from the adapter internal Bluetooth transmitter / receiver are copied into the data memory of the DUT. During programming or testing any measurement or status values will not be displayed.Only at the end of the test run, there is a visual signaling on the test status with indication of error codes. The resultant data will also be transferred to a server for analysis efficiency.

The improvement

To optimize test time 3.0 multiple programming devices and interfaces are installed in the current test adapter version enabling parallel testing. TestStand gave this the ideal platform for test time reduction. For this purpose, the adapter internal relay board has been rebuilt to integrate fully to other hardware.

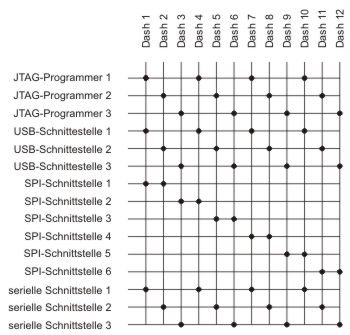

In V3.0 used interfaces and power supplies:

- 6x SPI interface

- 3x JTAG programmer

- 3x USB interface

- 3x serial interface

- 6x 5V power supply

- 3x 3.9V power supply

- 2x variable power supply

- 1x Bluetooth transmitter / receiver

The way from sequential to parallel test runs was because of TestStand relatively easy to implement. However, a priority method lacked preferable to access the hardware being used, which allows certain benefits during the execution of the test steps. This was necessary because one of the tests took a relatively long time to complete and the available hardware resources should be optimally used. The test and programming time was reduced by 80% from Version 1.0 to Version 3.0

The method used was that the individual test calls have doubled in the main sequence. As precondition were the first test call the prioritized sockets assigned, the second with lesser priority. Thus, the model waited always the first call and reached the second call after activating the sockets for the corresponding curly test. This could be largely controlled and the test procedure can be further optimized in a relatively simple way of access to the individual sockets.